Cocoa Processing Production Line

We offer a complete turnkey engineering solution for processing cocoa beans into cocoa butter and cocoa powder. Featuring a modular design, it provides a customizable capacity range from 50 to 1500 kg/h, specifically tailored for medium to large-scale processing plants.

Cocoa Powder

Cocoa Butter

Cocoa Liquor

Versatile & Multi-Purpose: Processes cocoa, peanuts, cashews, spices, and more. Maximizes your return on investment.

High Performance & Reliable: Achieves over 98% shelling rate with adjustable grinding fineness (12-120 mesh) for professional results.

Fully Customizable: Capacity from 50 to 1500 kg/h. Tailored voltage, heating (electric/gas), and packaging solutions.

Premium & Durable: Built with food-grade 304/316 stainless steel for hygiene, safety, and long-term durability.

Complete Lifecycle Support: 12-month warranty, lifetime tech support, free training, on-site installation, and export services.

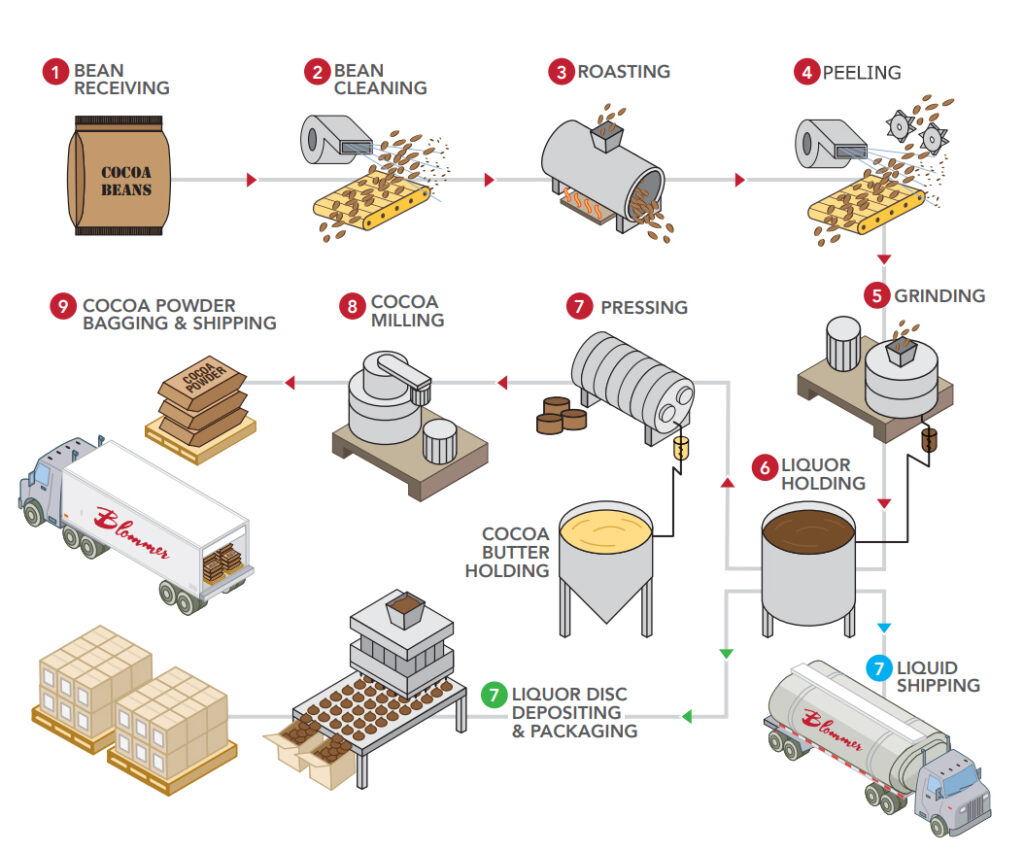

Cocoa Processing Production line Flow chat

Bean Destoner Technical Overview

Working Principle: Separates stones and heavy impurities from grains/nuts based on differences in density and size using vibration and airflow.

Material Construction: All food-contact surfaces are made of food-grade 304 stainless steel, ensuring hygiene and durability.

Technical Advantages: Features high-precision sensors and an optimized screening deck for high removal efficiency with minimal product loss.

Optional Configurations: Available with electric motor or pneumatic drive to suit different factory power setups.

Cocoa Bean Roaster Features

Principle: Indirect heat with a rotating drum for even roasting.

Material: Food-grade 304 stainless steel contact parts.

Advantages: Multi-stage temperature control for flavor; uniform roasting.

Options: Electric, gas, or steam heating; PLC automation available.

Cocoa Bean Peeling Features

Principle: Uses a combination of cracking, airflow, and vibration to separate shells from nibs.

Material: Key components made of food-grade 304 stainless steel.

Advantages: High peeling rate (≥98%) with low kernel damage.

Options: Adjustable for different bean sizes; can be integrated into a full processing line.

Cocoa Liquor Grinding Machine

Principle: Grinds cocoa nibs into liquor (mass) through cutting and pulverizing.

Material: Simple and safe structure, easy to operate and clean.

Advantages: Adjustable grinding fineness; retains the original flavor of cocoa butter.

Cocoa Butter Press Machine

Principle: Uses mechanical pressure to extract cocoa butter from cocoa liquor (paste), simultaneously producing solid cocoa cake.

Material: Constructed with durable stainless steel materials.

Advantages: Employs cold-pressing technology suitable for heat-sensitive, high-oil content crops; helps retain the original flavor of the cocoa butter.

Cocoa Cake Crusher

Principle: Crushes the hard cocoa cake into smaller particles in preparation for fine grinding into powder.

Material: Entire machine made of stainless steel.

Advantages: Simple structure, easy to clean and maintain; operates with low noise.

Cocoa Powder Milling Machine

Principle: Uses high-speed gear impact and friction to crush cocoa cake into fine powder.

Material: Whole machine made of stainless steel.

Advantages: Adjustable powder fineness (12 to 120 mesh) by changing the mesh screen.

Equipment Characteristics

Dual dedicated filling systems for cocoa powder and molten cocoa butter/liquor.

Working Principle

Auger dosing for powder; pump-and-weigh filling for liquids.

Material Construction

Food-grade 304 stainless steel contact surfaces.

Technical Advantages

High precision and dedicated temperature control.

Optional Configuration

Customizable heating systems and automation.

Technical Specs & Custom Options

Technical Parameters of 500 kg/h Cocoa Processing Line

Detailed technical specifications and performance indicators for medium to large-scale cocoa processing plants

| Process Section | Total Power | Key Capacity/Process Indicators | Key Technical Specifications |

|---|---|---|---|

| 1. Cleaning | 4.3 kW | Capacity: 500–1500 kg/h | Stone removal by specific gravity, with fan and booster system |

| 2. Roasting | 0.75 kW | Capacity: 500 kg/h | Electric heating, suitable for various nuts and beans |

| 3. Peeling & Cooling | 8.5 kW | Cooling: 500–1000 kg/h Peeling: 400–500 kg/h |

Peeling rate ≥98%, with vacuum suction for husk removal |

| 4. Grinding (Liquor) | 30 kW | Capacity: 500 kg/h | Double motor grinding, fine texture output |

| 5. Pressing (Butter) | 4 kW | Pressure: 55–60 MPa Batch: 20 kg |

Hydraulic system, max working pressure 1900 kN |

| 6. Crushing (Cake) | 11 kW | Capacity: 600 kg/h | Coarse crushing, feed inlet 500×250 mm |

| 7. Milling (Powder) | 11 kW | Capacity: 500–800 kg/h Fineness: 20–120 mesh |

Fineness adjustable, speed 3400 rpm |

| 8. Packaging | 4.9 kW | Powder: 5–25 kg/bag, ±0.2% Liquor/Butter: 50–60 boxes/h |

PLC control, touch screen, servo motor, dust removal included |

| Auxiliary (Air Supply) | 3.2 kW | Pressure: 7 Bar, 240 L/min | Tank: 120 L, for pneumatic systems |

Note: Above parameters are for standard 500kg/h configuration, customizable according to actual requirements.

Customize Your Production Line

We can tailor solutions to your specific needs.

- Capacity: Ranging from 50kg/h to 500kg/h or even higher.

- Energy Source: Electric heating, gas heating, or steam heating.

- Automation Level: From semi-automatic to fully automatic PLC control.

- Product Line Extension: Integration with packaging machines, palletizers, and other equipment is available.

- Workshop Layout: Non-standard design and installation guidance are provided.

Share your needs with us, and our engineers will deliver a preliminary draft proposal within 24 hours.

Preliminary Plan Delivered in

24 Hours

Why Choose Us

Turnkey Solution

Our turnkey solution delivers a ready-to-run cocoa processing plant, managed from concept to operation, so you can start production seamlessly.

Turnaround Time: 45-60 Days

Value-Optimized Solution

We design value-optimized solutions that strike the perfect balance between your performance needs, budget, and future scalability to maximize your long-term return on investment.

Optimal Value Investing Strategy

Extended Warranty

Our Extended Warranty Program covers the entire machine for 12 months, key components for 24 months, and is backed by lifetime technical support.

24-Hour Response Guarantee

Global Service Network

Our Global Service Network delivers full support—from remote guidance and on-site installation to hands-on training—across more than 50 countries and regions.

Coverage Area: 50+ Countries

Request Your Customized Solution and Quotation

Submit Requirements → Detailed Proposal in 24h